| Starch Films | ||||

| Trial | Starch Volume (mL) | Glycerin Volume (mL) | Vinegar Volume (mL) | Water Volume (mL) |

| 1 | 15 | 5 | 5 | 60 |

| 2 | 7 | 3 | 2.5 | 30 |

In addition to the synthesis of starch-based polymer films, a PLA film was also synthesized in order to use as a control group for future composite films. The method of synthesizing the PLA films involved completely dissolving the PLA in chloroform and then allowing the chloroform to dry off in a petri dish and reveal a thin PLA film. First, the thickness of the film was chosen to be 0.05 mm, based on research of the thickness of commercial garbage bags. To calculate the amount of PLA necessary to form a 0.05 mm film, the surface area of the petri dish was measured and multiplied by the desired film thickness to obtain the necessary volume of PLA. The calculated volume was 0.3619 mL. Then, the density of PLA, 1.24 g/mL, was used to determine the required mass of PLA, which was 0.44885 g. A solution of 3% PLA to 97% chloroform by mass was favorable in order to create the films, so 14.96 g of chloroform was the proper quantity. This value for mass was converted to 10.11 mL using the density of chloroform, which was 1.48 g/mL.

After calculating and measuring out the materials, the PLA and chloroform were thoroughly mixed for about 30 minutes using a magnetic stir bar. The resulting solution was poured into a petri dish in order to dry for 3 days. Then, the petri dish with the film was placed in an oven at 60 degrees Celsius for 24 hours. The final dried PLA film was then delicately extracted from the dish using tweezers.

Starch Polymer Film Synthesis:

Starch, Water, Glycerin, and Vinegar mixed and heated in a beaker on a hot plate

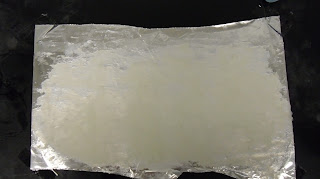

Starch Polymer Mixture Spread on Aluminum Foil

Resulting Starch Film on Aluminum Foil

No comments:

Post a Comment